Machining to meet your needs.

BlueRing’s Machining Capabilities

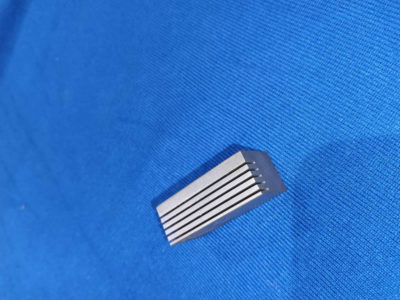

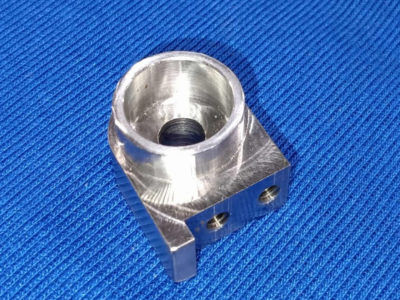

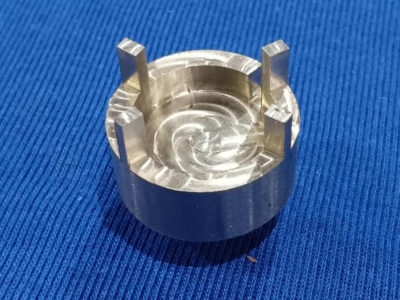

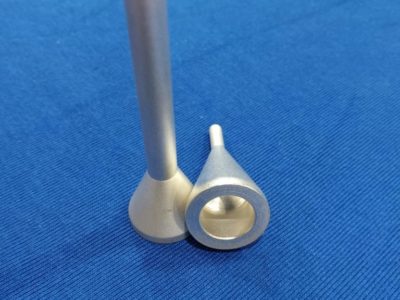

In addition to the tooling capabilities that we’re known for, BlueRing Machining also machines parts of different types and materials. Our workshop is equipped with a variety of equipment that allows us to machine parts to various specifications and from different materials (see details and examples below). Our highly experienced team allows for quick turn-around times and high quality work. We work directly with our customers to deliver the best experience possible.

Get in touch with us for a quote or to inquire about our capabilities for a specific project.

Our Machining Equipment

5 CNC Mills-

HAAS VF-3

20 Tool Turret

Work Area: 40” X 20” Y 20” Z

10,000 RPM

(3) HAAS VF-4

30 Tool Turret

Renishaw Wireless Intuitive Probing System

Work Area: 50” X 20” Y 25” Z

10,000 RPM

HAAS VF-5

30 Tool Turret

Work Area: 50” X 26” Y 25” Z

10,000 RPM

7 AXIS MIYANO BNE-345

12 Ft. Automatic Bar Feeder

12 Station Upper Turret (6 stations support live tooling)

10 station Lower Turret

2 spindles @ 5000 RPM

2 AXIS MIYANO-34

12 Ft. Automatic Bar Feeder

6 station Turret

1 spindle @ 4500 RPM

2 Manual Lathes-

Victor-1640

Maximum Swing: 16″

Distance Between Centers: 40″

Spindle Speed: 1,800 RPM Max.

Hole Through Spindle: 2.25″

Kingston HJ-1100

Maximum Swing: 17″

Distance Between Centers: 43.5″

Spindle Speed: 2,000 RPM Max.

Hole Through Spindle: 2.25″

4 Manual Vertical Mills-

(3) Seiki XL 3VH & (1) Lagun FTV-2

Work Area 10” x 50”

4,200 Max RPM

Welding Equipment-

Miller Mig & Tig welders for Carbon Steel, Stainless Steel & Titanium

Our Material Capabilities

Plastics-

Delrin

HDPE

Teflon (PTFE)

UHMW (P)

Nylon

PVC

ABS

Polycarbonate

PEEK

Vespel

Metals-

Carbon Steel- 12L14, 1018, 1215….

Stainless Steel- 303, 304 & 416

Aluminum- Mic 6, 6061 & 7075

Tool Steel- A2 & S7

Titanium- Grades 2 & 5

Brass

Nickel

Copper

Composites-

Durostone (CAS761, CAG762 & WGR 781)

G10/FR4

Phenolic